Sensor Deck Mounted Tap / Small

View downloads- European Infra-Red sensor Technology

- Delivers luxurious user experience

- Efficient water-saving design

Clean lines. Clean design. Clean hands.

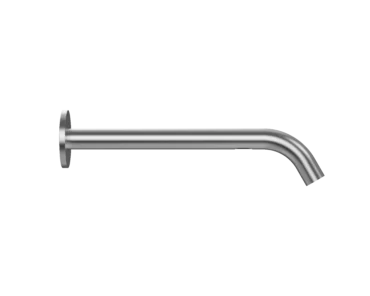

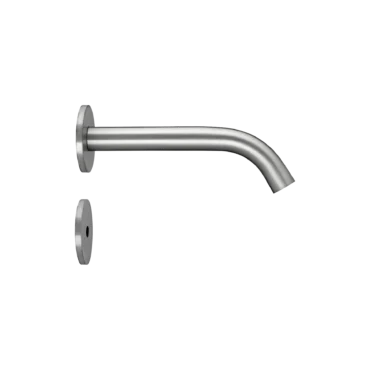

The simplicity of form and clean lines allow the TSL.990 IR sensor tap to work across many design intents, and its thoughtful proportions have been calculated to complement our Monolith Basin System and deck mounted soap dispenser range. Bauhaus inspired, the TSL.990 is milled from solid stainless steel and is available in our 4 signature PVD finishes.

The TSL.990 utilises robust Infra-Red technology, offering sensor stability and longevity which is critical when specifying in public or semi-public spaces, such as busy offices.

Every product in the range also benefits from an anti-rotation collar, which in addition to the solid steel construction gives them durability which belies their slender looks. The tap offers the flexibility of power source; either mains or battery, which can be helpful when specifying retrofit schemes.

Sustainable and beautiful

With clients rightly more conscious of ongoing operational costs and sustainability when selecting products for their space, our design attention has been focused on reducing the water flow of this deck mounted sensor tap range, without compromising on user experience.

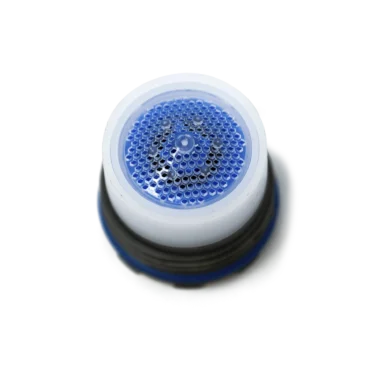

By the implementation of a cascade aerator to control the flow rate to 1.8L/min, the TSL.990 achieves the highest BREEAM and LEED standards whilst delivering a soft and luxurious water delivery to the hands. Lower flow rates can also be achieved if needed. This product is WRAS approved.

Consistent visual language

Another subtle but critical benefit of specifying the TSL.990 alongside any other product within the TSL range, is the consistency of both colour and material finish and the ability to retain a consistent visual language across the whole washroom; paramount for a cohesive user experience.

We help you achieve consistency in your restroom not just through complementary product forms but also via our signature brushed stainless steel and curated palette of rich, coloured PVD finishes.

Our attention to detail, quality assurance and high level of craftsmanship results in simple design solutions that make public and commercial washroom environments not just better, but beautiful.

Technical Data: Mechanical

Weight

1.4KgMaterial

AISI 304 Stainless SteelMin/Max pressure

0.5 - 7.5 barFlow Rate

3.8 litres/minute; also available - 1.3l/min spray, 1.89l/min sprayAerator

Cascade flowCoating Type

PVD (colours only)Max hot water temperature

60°CTemperature control

Internal mixer cartridge; not thermostaticTechnical Data: Electrical

Power Supply (Battery)

6V CR-P2 Lithium BatteryPower Supply (Mains)

100-240V; 1.5A; 50-60Hz PSU.Output (Max)

6V; 6W maxPower Consumption

< 80μASolenoid Valve

6VWater Ingress (PSU)

IP67Cable Lengths

Connection to sensor cable - 400mmConnection to fused supply - 1.5m

Technical Data: Sensor

Sensor Type

Infra redPre-set sensor range

120mmMaximum sensor range

250mmComfort Delay

2 secondsSecurity Time-out

30 secondsOperating Temperature

0 to 50oCResponse Time (max)

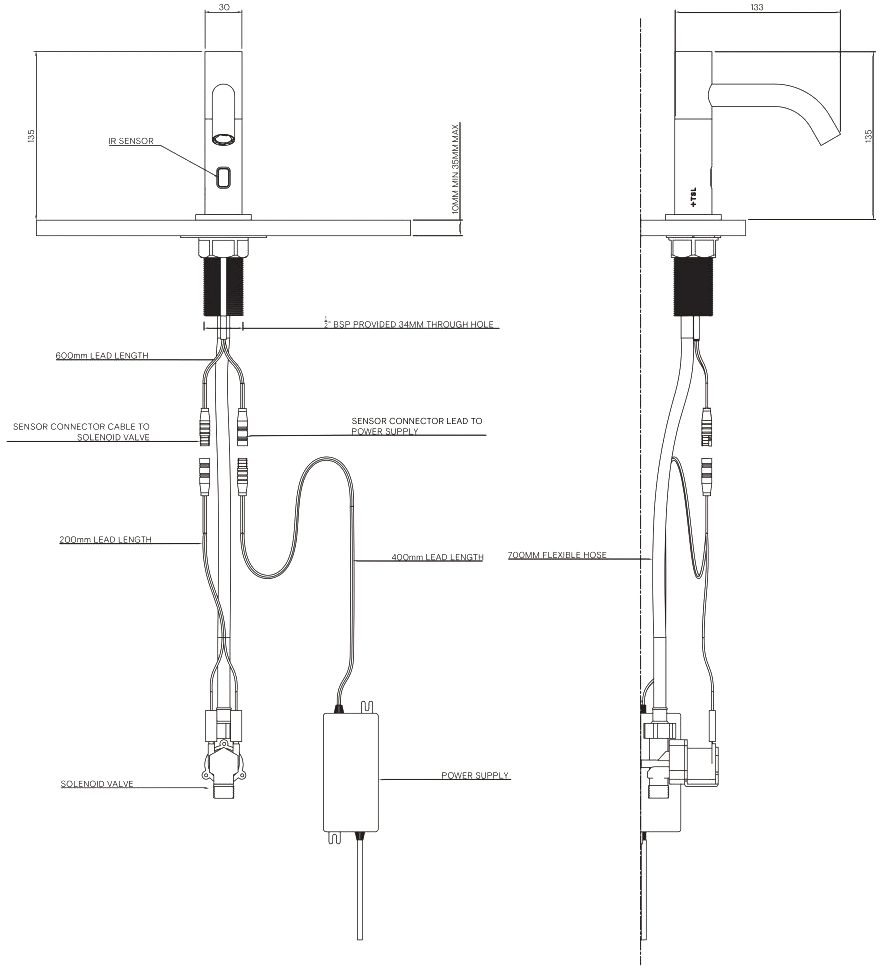

< 300msTechnical Drawing

Related projects

View allThe Splash Lab go above and beyond to make sure the end product is exactly as designed and functioning as intended.International Design Firm

Begin making the essential, exceptional.

Sensor Deck Mounted Tap / Small

TSL.990Welcome to the support page for the TSL.990 Sensor Deck Mounted Tap (small). On this page you’ll find video guides to repairs, common fixes, and general repairs. Plus there is a list of FAQs you may find helpful. If none of this answers your question. Please don’t hesitate to get in touch.

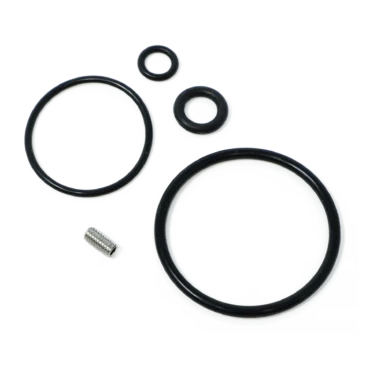

Spares & accessories

FAQs

The average lead time on all our products is currently 6 to 8 weeks.

The flow rate of our taps is dependent on which flow restrictor is fitted and the pressure achieved in your installation. TSL990 & TSL 960 come with a 3.8 (1 gallon) per minute flow restrictor.

The most likely cause is no power to the tap either 230V to the power pack or 6v from the power pack to the sensor. Please check there is a 6v supply from the power pack to the sensor, the easiest way to do this is to plug in to a neighbouring tap and check the function. If the tap is in a location on its own use a voltmeter to check.

If 6v is not present between the power pack and the sensor, please check that the 230V supply is present to the power pack.

No 230v to power pack – Contact an electrician to investigate.

230v present but no 6v – Contact technical@thesplashlab.com to source a replacement power pack.

230v and 6v present – Refer to How do I adjust the sensor range of my tap for further guidance.

All of our sensors are calibrated for the specific tap dimensions, however during installation and dependent on the order the sensor is powered up it is possible the sensor range could have been inadvertently changed.

If the sensor range has been extended it may pick up the basin below and run for its max time of 30 seconds. As the sensor is still picking up the object below it is effectively locked out, this is a security feature to prevent flooding if the basin is blocked.

Reducing the sensor range by either purchasing a remote control or using the manual method will rectify the issue. Please refer to How do I adjust the sensor range on my tap for further guidance.

There are two main causes of a sensor tap running constantly.

No power to the sensor. If the valve is in the open position and there is no power the valve may not be able to close. Please check there is 230v power to the power pack and there is 6v power from the power pack to the sensor.

Dirt or debris in the valve housing can prevent the diaphragm from creating a full seal. If this is the issue you are experiencing the flow rate should not be full rate. Following the cleaning guide in Why is my tap dripping and how do I fix it, which should resolve this issue.

A Most dripping taps are caused by a foreign object being present in the valve between the diaphragm and the valve seating, simply cleaning out the valve will stop the dripping in most cases.

To clean out the valve:

Isolate the water to the valve.

Remove the valve from the pipework.

Remove the 3 screws holding electromagnet to the valve body.

Lift the magnet away, please note the orientation and location of the components inside

Remove the diaphragm and rinse with clean water.

Rinse the valve body.

Reassemble ensuring the spring and pin are returned to their original orientation.

Fit back to the pipework and test.

If these steps do not stop the dripping the diaphragm may need replacing, please contact technical@thesplashlab.com for further assistance.

Any spare parts related to your product can be found above. If you would like to see our full range of spare parts please click here.

Yes, we can offer an installation service to suit your needs. Please contact technical@thesplashlab.com with details of your requirements and we will be happy to assist.

Common fixes

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

Related projects

View allThe Splash Lab go above and beyond to make sure the end product is exactly as designed and functioning as intended.International Design Firm