150mm IR Sensor Tap

View downloads- Sleek design at optimal length

- Easy installation and maintenance

- Robust design suits high-traffic public wash spaces

- Successful in commercial setting

Slim, aesthetic, market-leading, technologically advanced, and not an iPhone.

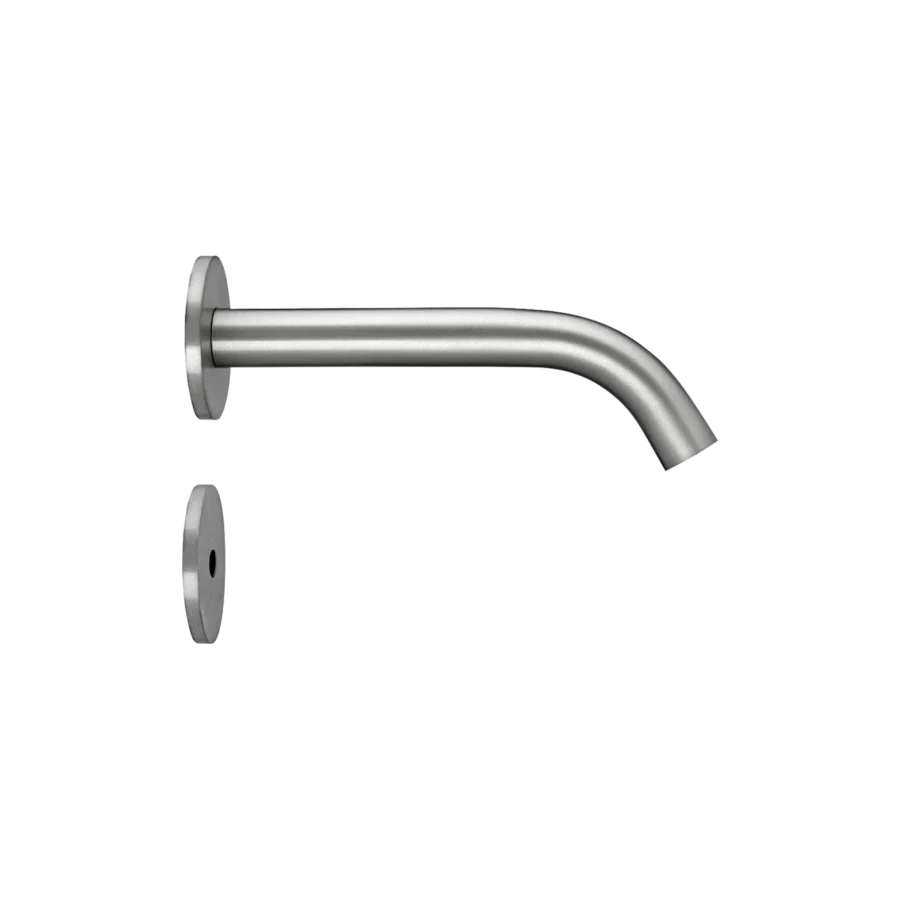

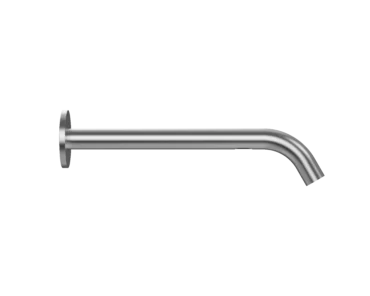

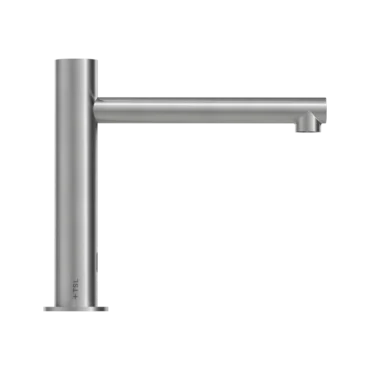

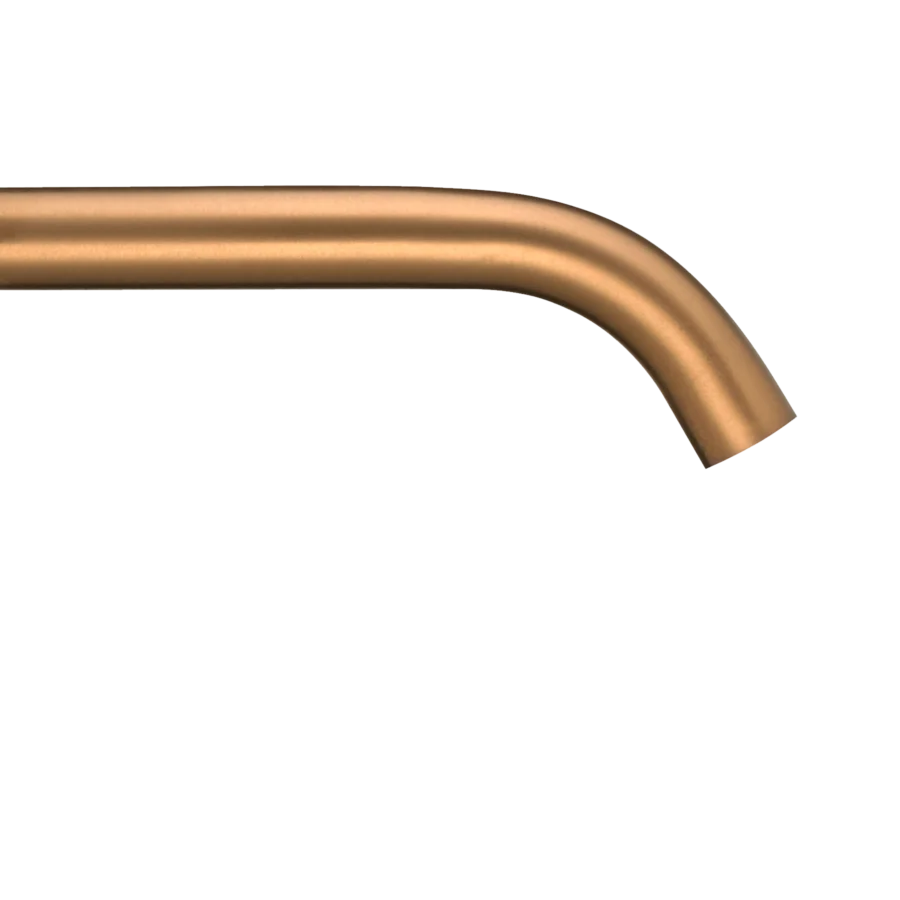

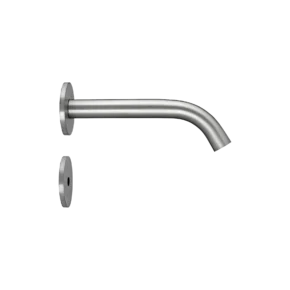

The sleek TSL.884 & TSL.886 Infrared Sensor Tap features an elegant, minimalist 150mm wall-mounted spout machined from AISI304 stainless steel. A separate sensor housing, also crafted in matching stainless steel, is designed to be affixed directly under the spout. This tap has been designed to work perfectly in a superloo environment alongside our Monolith Basin System, at an optimal length of 150mm

Easy to install, this WRAS approved infrared sensor tap can be operated using either mains or battery power and is robust enough to be suitable for high-traffic public or commercial washrooms. With a flow rate of 1.9L/min or 3.8L/min, an operating pressure of 0.2 to 8 Bar and an IR sensor range of 50mm to 120mm, it’s an easy-to-use washspace™ option. Both BREEAM and DDA compliant, this refined, minimalist tap comes in five metallic PVD finishes in brushed stainless steel.

Infrared sensor taps with contemporary finishes

The stylish WRAS approved TSL.884 IR sensor tap can be specified in five different finishes so you can achieve a public or commercial restroom with refined aesthetics. We offer coloured IR sensor taps in Black (BK), Brass, (BR), Copper (CP), Satin (CS).

We create our finishes using Physical Vapour Deposition (PVD). This process creates rich coloured stainless steel by coating it with Titanium Ion Plating. More environmentally friendly than electroplating or powder coating, this superior process improves the performance of stainless steel by increasing its durability and abrasion, scratch and corrosion resistance. The 0.5-micron thick coating hardens the surface, giving it good impact strength and making it so durable that protective topcoats are almost never necessary.

To specify your finish, please add the finish suffix to the main product code. For example, to order the TSL.884 IR Sensor Tap in Copper, the code would be TSL.884.CP.

How to create a consistent design look in your washroom

At The Splash Lab, we design and manufacture our own commercial washroom products that work together to create a consistent design language in your washspace™. We help you achieve consistency in your restroom not just through complementary product forms but also via our signature brushed stainless steel and curated palette of rich, coloured PVD finishes.

Our attention to detail, quality assurance and high level of craftsmanship results in simple design solutions that make public and commercial washroom environments better and more beautiful.

Technical Data: Mechanical

Body Material

AISI 304 Stainless SteelCoating Type

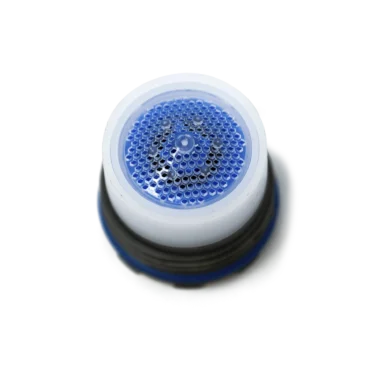

PVDAerator

CascadeWater Pressure (Dynamic)

0.5 to 7.5 Bar [0.05 to 0.75MPa]Water Temperature (max)

60°CFlow Rates

0.5gpm [1.9L/min]Also available

0.35gpm [1.3L/min] – refer to Spare Parts & Accessories1.00gpm [3.8L/min] – refer to Spare Parts & Accessories

Weight

1041gTechnical Data: Electrical

Power supply

TSL .884 110-230 Vac, 50-60Hz, 1.5A TSL .886 6 V CR-P2 Lithium batteryOutput (max)

6 Vdc, 1APower consumption

< 87% Active mode, 0.3W No loadSolenoid valve type

6V LatchingWater Ingress

IP55Cable lengths

800mm – Power supply connection800mm – Solenoid valve connection

Technical drawings

Installation Guidlines

Wall Cut-out Hole Size

Ø16mm (Spigot)Ø40mm (Sensor Housing)

Depth of Wall Cavity (min)

100mmWall Thickness (max)

50mm (incl. finishes)Plumbing Connection

1⁄2” BSP (female) brass fitting is required to connect to the solenoid valve housingPower supply cable

To be hard wired in to fused connection unit (FCU) or spurWater supply

1.0 Bar is the recommended minimum pressure for the taps to operate effectively.7.5 Bar is the maximum pressure for commissioning and is NOT recommended for general use.

Gravity-fed systems may require a booster pump to achieve the optimal operating pressure

All pipework must be thoroughly cleaned and clear of any debris before connecting the tap.

Washroom layout

Solenoid valve must be accessible for installation, commissioning and ongoing maintenance.Avoid installing the sensor tap directly opposite other sensor taps, soap dispensers, infrared devices or reflective surfaces.

Careful consideration should be made when choosing the positioning of lighting and other reflective surfaces which may affect sensor performance.

Related projects

View allThe Splash Lab go above and beyond to make sure the end product is exactly as designed and functioning as intended.International Design Firm

Begin making the essential, exceptional.

150mm IR Sensor Tap

TSL.884Welcome to the support page for the TSL.884 150mm IR Sensor Tap. On this page you’ll find video guides to repairs, common fixes, and general repairs. Plus there is a list of FAQs you may find helpful. If none of this answers your question. Please don’t hesitate to get in touch.

Spares & accessories

FAQs

The average lead time on all our products is currently 6 to 8 weeks.

There are two main causes of a sensor tap running constantly.

No power to the sensor. If the valve is in the open position and there is no power the valve may not be able to close. Please check there is 230v power to the power pack and there is 6v power from the power pack to the sensor.

Dirt or debris in the valve housing can prevent the diaphragm from creating a full seal. If this is the issue you are experiencing the flow rate should not be full rate. Following the cleaning guide in Why is my tap dripping and how do I fix it, which should resolve this issue.

Our solenoid valves work within a dynamic pressure of 0.5-8 Bar (7.3-116psi). To achieve optimal flow rate from the tap a regulated pressure of 3 bar(43.8psi) is recommended, pressures lower or higher than this will decrease the flow rate from the tap.

Pressures outside of the range may prevent the valve from opening and closing.

All of our taps are supplied by a mixed water supply via a Thermostatic Mixing Valve (not supplied) as part of the washrooms plumbing. There are no temperature controls within the tap, the temperature can only be adjusted via the TMV.

Any spare parts related to your product can be found above. If you would like to see our full range of spare parts please click here.

Yes, we can offer an installation service to suit your needs. Please contact technical@thesplashlab.com with details of your requirements and we will be happy to assist.

Common fixes

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

These videos are The Splash Lab TSL recommendations and any work, especially on electrical products, must be undertaken by a qualified professional. The Splash Lab (TSL) is not responsible for any event because of following the instructions in these videos

Related projects

View allThe Splash Lab go above and beyond to make sure the end product is exactly as designed and functioning as intended.International Design Firm