Since we launched the original Monolith Basin system in 2012, we have seen many imitators emerge in the market. Too often, we hear of the challenges they present at specification, installation, and post hand-over. We chose to write this 5 part comprehensive guide to give specifiers the core requirements for longevity, whichever solid surface basin you choose to specify.

We believe that the true sustainability is found in product longevity, complemented by a focus on materials. Apart from knowledge of the 10-year warranty that Corian provides, an educated specification requires a knowledge of the fabrication methods of solid surface trough basins to ensure that the wash trough will last for years after post completion, resulting in a satisfied client.

In 1963, the concept of solid surface was arrived at by a group of engineers and researchers from the DuPont™ Chemical Company.

Don Slocum, who was working at Dupont ™ at the time, wanted to create a material with the following properties:

In 1963, the concept of solid surface was arrived at by a group of engineers and researchers from the DuPont™ Chemical Company.

Don Slocum, who was working at Dupont ™ at the time, wanted to create a material with the following properties:

Each basin is drawn out in CAD/CAM to achieve maximum cutting efficiency on the CNC, with all the parts being nested. Once the solid surface arrives in sheets from the distributor, it is checked and placed, jigged and cut on the CNC saw to precisely machine the sheets to tight tolerances. These parts are then taken off the machine and all rough edges are removed by hand to ensure the assembly team have clean parts to work with.

Each basin is drawn out in CAD/CAM to achieve maximum cutting efficiency on the CNC, with all the parts being nested. Once the solid surface arrives in sheets from the distributor, it is checked and placed, jigged and cut on the CNC saw to precisely machine the sheets to tight tolerances. These parts are then taken off the machine and all rough edges are removed by hand to ensure the assembly team have clean parts to work with.

The assembly team dry fit the parts. Once satisfied, the parts are glued and clamped in place for several hours to achieve a strong joint.

The assembly team dry fit the parts. Once satisfied, the parts are glued and clamped in place for several hours to achieve a strong joint.

Each basin is hand finished by a master craftsman, ensuring all joints, surfaces and edges are perfect. This involves a mix of hand tool and power tool work to achieve the precise finish required.

Each basin is hand finished by a master craftsman, ensuring all joints, surfaces and edges are perfect. This involves a mix of hand tool and power tool work to achieve the precise finish required.

At the final work station, each basin is submitted to a detailed quality check, including joint integrity, water proofing, and a close look at the surface finish and basin geometry. Once the basin has been signed off by production management, the basin should be carefully placed into robust and transport proof packaging, along with any support and drainage components. We also include a solid surface care kit for the client maintenance team.

At the final work station, each basin is submitted to a detailed quality check, including joint integrity, water proofing, and a close look at the surface finish and basin geometry. Once the basin has been signed off by production management, the basin should be carefully placed into robust and transport proof packaging, along with any support and drainage components. We also include a solid surface care kit for the client maintenance team.

There are 5 key areas we recommend specifiers pay close attention to when specifying solid surface trough sinks:

There are 5 key areas we recommend specifiers pay close attention to when specifying solid surface trough sinks:

The simplest way of all, is to work with a manufacturer’s standard sizes. At The Splash Lab, we have multiple standard sizes within 3 heights, 5 lengths, and 3 depths, and any combination of these. This allows the Revit files, all downloadable from the site to be dropped straight into your project family and any parameters easily adjusted, whilst retaining all the correct structural specifications.

DOWNLOAD PARAMETRIC REVIT FAMILY

The simplest way of all, is to work with a manufacturer’s standard sizes. At The Splash Lab, we have multiple standard sizes within 3 heights, 5 lengths, and 3 depths, and any combination of these. This allows the Revit files, all downloadable from the site to be dropped straight into your project family and any parameters easily adjusted, whilst retaining all the correct structural specifications.

DOWNLOAD PARAMETRIC REVIT FAMILY

This covers adjustments of the basic parameters of the basin and may include custom elements such as:

Basin Length

Basin Height

Basin Depth

Inclusion of various standard modules such as waste bin chutes, coved corners, vanity units, and dividers. A list of the standard TSL modules can be found here.

DOWNLOAD PARAMETRIC REVIT FAMILY

This covers adjustments of the basic parameters of the basin and may include custom elements such as:

Basin Length

Basin Height

Basin Depth

Inclusion of various standard modules such as waste bin chutes, coved corners, vanity units, and dividers. A list of the standard TSL modules can be found here.

DOWNLOAD PARAMETRIC REVIT FAMILY

This can be where some of our most exciting projects emerge from. Starting from anything from a napkins sketch to a concept render from any of our specifier partners, we can then evaluate this, leveraging the proven principles of our basin system to deliver your vision. This was done to great effect at Westfield White City, working alongside their internal design team, moving from concepts to several full size MDF prototypes we finally delivered 27 basins from anywhere between 3 and 22 users creating an absolutely stunning washroom experience which matched the rest of the incredible interiors.

This can be where some of our most exciting projects emerge from. Starting from anything from a napkins sketch to a concept render from any of our specifier partners, we can then evaluate this, leveraging the proven principles of our basin system to deliver your vision. This was done to great effect at Westfield White City, working alongside their internal design team, moving from concepts to several full size MDF prototypes we finally delivered 27 basins from anywhere between 3 and 22 users creating an absolutely stunning washroom experience which matched the rest of the incredible interiors.

To get the ball rolling, drop a note to blake.anderson@thesplashlab.com.

To get the ball rolling, drop a note to blake.anderson@thesplashlab.com.

Contents

Starting with an understanding of the core principles & properties of the material, followed by the manufacturing process for quality solid surface basins. This guide also covers a definitive specifiers checklist, and ways to speed up your basin specification workflow in Revit, whether using standard size multi user basins, or creating a custom solid surface wash trough.- What is Solid Surface?

- Why Use Solid Surface in the Washroom?

- How are Solid Surface Basins Manufactured?

- Solid Surface Basin Specification Checklist

- Increasing Speed of Specification for Solid Surface Basins – Workflow Tips

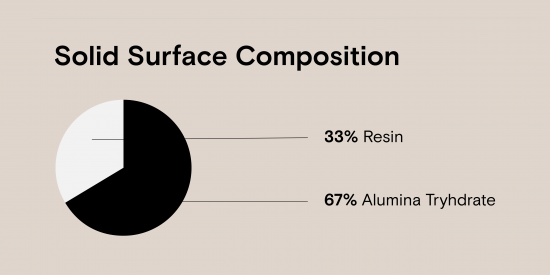

1: What is Solid Surface?

In 1963, the concept of solid surface was arrived at by a group of engineers and researchers from the DuPont™ Chemical Company.

Don Slocum, who was working at Dupont ™ at the time, wanted to create a material with the following properties:

In 1963, the concept of solid surface was arrived at by a group of engineers and researchers from the DuPont™ Chemical Company.

Don Slocum, who was working at Dupont ™ at the time, wanted to create a material with the following properties:

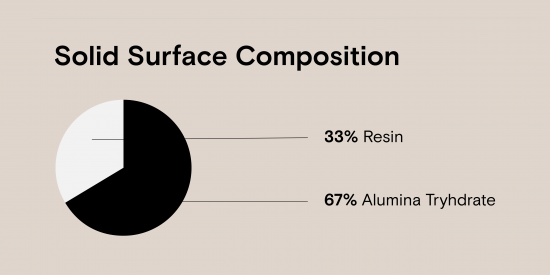

- Non porous

- Stain, chemical and fire resistant

- Solid all the way through

- Void of air bubbles

- Hard enough to be used as a work surface

- Easily repairable

- Rich and pleasing look

- Had a consistency of pattern and colour

- Finally, it had to be able to be worked with standard woodworking tools.

2: Key Benefits of using Solid Surface in the Washroom

Easily repairable

In addition to the ability to be able to invisibly repair Corian, through sanding and filling in. This factor also allows the basins to be invisibly seamed on site to allow very long lengths and complex shapes to be used. We have created Corian trough basins up to 8 metres long at the Splash Lab, and basins that go around corners.Non-Porous

Corian is completely non-porous, so unlike natural stone requires no additional sealing. This is particularly important in washrooms and other high moisture areas, as the integrity of the material can never be compromised.Colour Availability

With Corian and the advent of many other solid surface manufacturers, there are hundreds of colours available for use in creating your trough basin. Please always check with your manufacturer before specifying a colour, as certain colours, including some of the darker colours can be more prone to scratching, and some of the more patterned finishes cannot be seamlessly jointed.Consistency of Pattern & Colour

This is key where multiple sheets and batches may be being used in a single washroom. Although, as with any material, you may get a very slight variation batch to batch, it is very consistent in terms of finish. This is true from the simplest colours such as Glacier White through to something more complex such as Grey Onyx.Hard Wearing

Solid Surface is a hard wearing and resilient material. Any scratches can be easily buffed out with a small amount of sand paper, making it look as good as new. This is crucial, particularly in high traffic washroom areas, such as airports and shopping malls.3: How are solid surface basins manufactured?

The steps in solid surface basin fabrication are extremely important, in order to create a consistent product as a repeatable process. At The Splash Lab, each Corian basin is processed through 4 stages, each requiring a trained eye, and attention to detail.Cut

Each basin is drawn out in CAD/CAM to achieve maximum cutting efficiency on the CNC, with all the parts being nested. Once the solid surface arrives in sheets from the distributor, it is checked and placed, jigged and cut on the CNC saw to precisely machine the sheets to tight tolerances. These parts are then taken off the machine and all rough edges are removed by hand to ensure the assembly team have clean parts to work with.

Each basin is drawn out in CAD/CAM to achieve maximum cutting efficiency on the CNC, with all the parts being nested. Once the solid surface arrives in sheets from the distributor, it is checked and placed, jigged and cut on the CNC saw to precisely machine the sheets to tight tolerances. These parts are then taken off the machine and all rough edges are removed by hand to ensure the assembly team have clean parts to work with.

Assemble

The assembly team dry fit the parts. Once satisfied, the parts are glued and clamped in place for several hours to achieve a strong joint.

The assembly team dry fit the parts. Once satisfied, the parts are glued and clamped in place for several hours to achieve a strong joint.

Finish

Each basin is hand finished by a master craftsman, ensuring all joints, surfaces and edges are perfect. This involves a mix of hand tool and power tool work to achieve the precise finish required.

Each basin is hand finished by a master craftsman, ensuring all joints, surfaces and edges are perfect. This involves a mix of hand tool and power tool work to achieve the precise finish required.

Quality Assurance & Packing

At the final work station, each basin is submitted to a detailed quality check, including joint integrity, water proofing, and a close look at the surface finish and basin geometry. Once the basin has been signed off by production management, the basin should be carefully placed into robust and transport proof packaging, along with any support and drainage components. We also include a solid surface care kit for the client maintenance team.

At the final work station, each basin is submitted to a detailed quality check, including joint integrity, water proofing, and a close look at the surface finish and basin geometry. Once the basin has been signed off by production management, the basin should be carefully placed into robust and transport proof packaging, along with any support and drainage components. We also include a solid surface care kit for the client maintenance team.

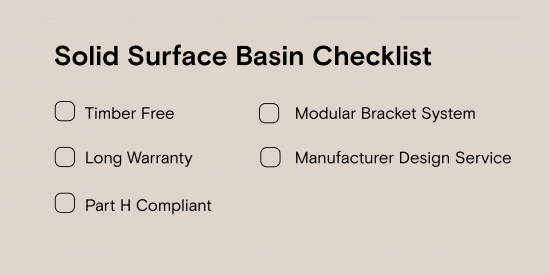

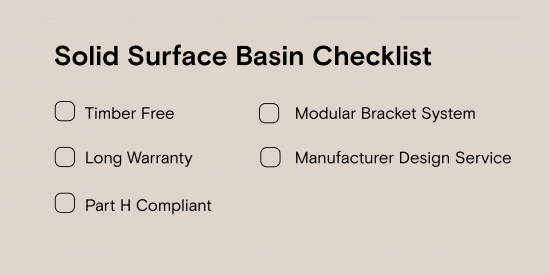

4: Solid Surface Basin Specification – Checklist

There are 5 key areas we recommend specifiers pay close attention to when specifying solid surface trough sinks:

There are 5 key areas we recommend specifiers pay close attention to when specifying solid surface trough sinks:

Timber Free

The number one element to avoid is timber. We can’t stress this enough. A traditional fabrication of a solid surface sink uses timber in 2 places – both of which must absolutely be avoided if your client would like their Corian sink to last more than a decade.- A timber sub frame.

- Ply backing on the Corian basin

Warranty:

Corian provide a 10 year warranty on their sheet material, so as a minimum, if Corian is being used – this should be offered to your client. In addition to this, ensure that the manufacturers also carry a workmanship warranty, not just a warranty against material defect. We resolutely believe that solid surface trough sinks manufactured to a high standard, in conjunction with a quality choice of material should last at least a decade, and the makers should be prepared to stand behind their work.Modular Bracket System:

To have any hope of quick installation, ensure the solid surface basin is equipped with a modular metal bracket system. The traditional method of mounting a basin on a fabricated timber sub frame requires the co-ordination of 2 trades – plumbing and joinery. With a simple steel support system, the whole thing can be fixed in place by the M & E contractor requiring no bespoke joinery. It also means that the basin is supported within proven load bearings and flex tolerances, which along with the warranty can provide you with total peace of mind.Part H Compliant Drainage

Part H of the UK Building Regulations pertains to Drainage & Waste Disposal, and has to be taken into consideration which specifying a solid surface sink. Many proposed alternative solid surface sinks we see do not comply. Part H 1.3 – 1.6 states: 1.3: All points of discharge into the system should be fitted with a trap (e.g. a water seal trap) to prevent foul air from the system entering the building. Under working and testing conditions traps should retain a minimum seal of 25mm of water or equivalent. 1.4: Washbasin should have a minimum 32mm diameter trap and 75mm depth of seal. 1.5: Pressure Fluctuation: To prevent the water seal from being broken by the pressures which can develop in the system the branch as per clause 1.7 to 1.25 1.6: Access for clearing blockages – If a trap forms part of an appliance the appliance should be removable. All other traps should be fitted directly after the appliance and should be removable or be fitted with a cleaning eye. To comply with Part H requirements, all basins in a public/semi-public space must be accessible. We have come across multiple situation in which the drainage has been fixed to the basin using adhesive and silicone. Best practice here is to use a mechanical fix with a removable seal. These allows any build up to be cleaned.Utilise a proven system within house design capabilities

On any project where yours and the client’s reputation is on the line for the quality and execution of a project, the last thing you want in one of the most used rooms in the building is an unproven product with the liability resting on you. Our aim with this post is to help you understand how to specify corian sinks that you can rely on. Ensure your provider has design and development expertise and experience for any custom or bespoke projects particularly. As a specifier, you have enough to think about without worrying about the construction execution of a product concept. You should be able to put that in the hands of someone who has expertise in executing on products like this to ensure all regulatory, user experience criteria are met without compromising on aesthetics.5: Specification Process – Increasing Workflow for Solid Surface Basin Specification

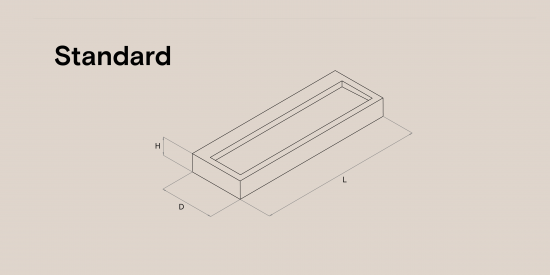

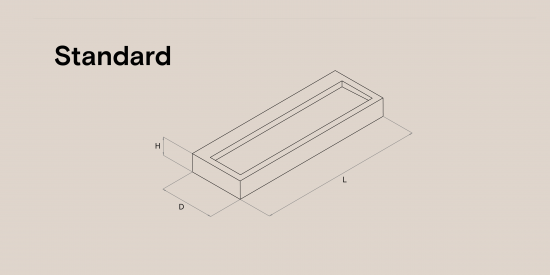

We also wanted to share some best practices we have learnt around the physical specification of solid surface basin, whether they be single user, 2,3, 4 or even 5 + users with customisations. This section is split into specifying standard size sinks, and then diving into how to specify custom solid surface sinks.Specifying standard solid surface basin sizes

The simplest way of all, is to work with a manufacturer’s standard sizes. At The Splash Lab, we have multiple standard sizes within 3 heights, 5 lengths, and 3 depths, and any combination of these. This allows the Revit files, all downloadable from the site to be dropped straight into your project family and any parameters easily adjusted, whilst retaining all the correct structural specifications.

DOWNLOAD PARAMETRIC REVIT FAMILY

The simplest way of all, is to work with a manufacturer’s standard sizes. At The Splash Lab, we have multiple standard sizes within 3 heights, 5 lengths, and 3 depths, and any combination of these. This allows the Revit files, all downloadable from the site to be dropped straight into your project family and any parameters easily adjusted, whilst retaining all the correct structural specifications.

DOWNLOAD PARAMETRIC REVIT FAMILY

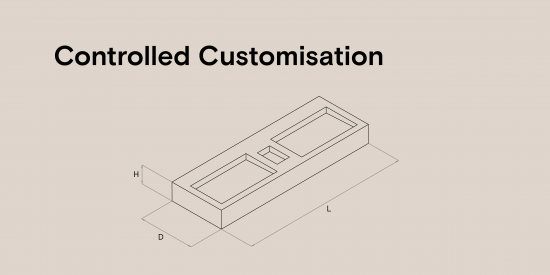

Specifying a custom solid surface basin

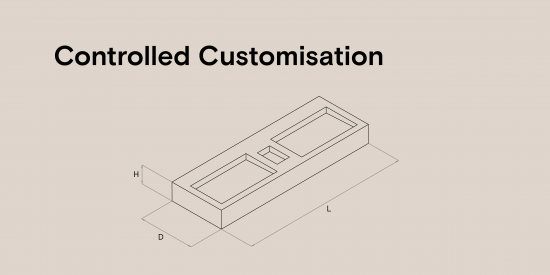

At The Splash Lab, we talk about 2 levels of customisation 1: Controlled Customisation 2: Bespoke This section looks at each, and offers ways to quickly and correctly specify either.1: Controlled Customisation

This covers adjustments of the basic parameters of the basin and may include custom elements such as:

Basin Length

Basin Height

Basin Depth

Inclusion of various standard modules such as waste bin chutes, coved corners, vanity units, and dividers. A list of the standard TSL modules can be found here.

DOWNLOAD PARAMETRIC REVIT FAMILY

This covers adjustments of the basic parameters of the basin and may include custom elements such as:

Basin Length

Basin Height

Basin Depth

Inclusion of various standard modules such as waste bin chutes, coved corners, vanity units, and dividers. A list of the standard TSL modules can be found here.

DOWNLOAD PARAMETRIC REVIT FAMILY

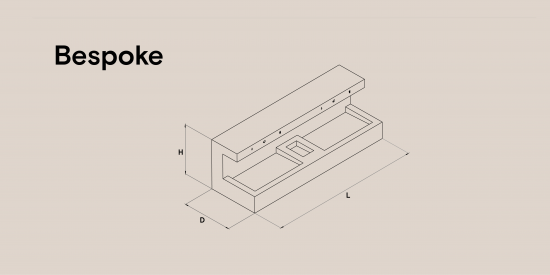

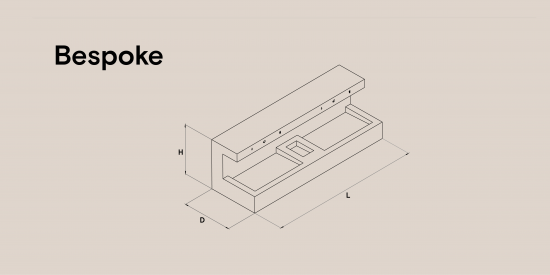

2: Bespoke

This can be where some of our most exciting projects emerge from. Starting from anything from a napkins sketch to a concept render from any of our specifier partners, we can then evaluate this, leveraging the proven principles of our basin system to deliver your vision. This was done to great effect at Westfield White City, working alongside their internal design team, moving from concepts to several full size MDF prototypes we finally delivered 27 basins from anywhere between 3 and 22 users creating an absolutely stunning washroom experience which matched the rest of the incredible interiors.

This can be where some of our most exciting projects emerge from. Starting from anything from a napkins sketch to a concept render from any of our specifier partners, we can then evaluate this, leveraging the proven principles of our basin system to deliver your vision. This was done to great effect at Westfield White City, working alongside their internal design team, moving from concepts to several full size MDF prototypes we finally delivered 27 basins from anywhere between 3 and 22 users creating an absolutely stunning washroom experience which matched the rest of the incredible interiors.

To get the ball rolling, drop a note to blake.anderson@thesplashlab.com.

To get the ball rolling, drop a note to blake.anderson@thesplashlab.com.